Many Ponds and Lakes are located in remote locations and require treatment to reduce algae formation and lake turnover. Because most treatment for these lakes is carried out in periods in which there is significant sunlight, remote lakes are good candidates for use of solar power The full treatment protocol can include herbicide application, surface fountains to aerate the water, bottom aerators for bodies of water greater than 10 feet in depth to prevent “Turnover” and possibly Grass Carp to eliminate lake debris. The lake pumps, lights, cameras and compressors can be powered by Solar Energy These solar energy systems can utilize AC(Alternating Current) , DC(Direct Current) or a combination of both.

Two cases are given below:

Remote 1.7 Acre Lake

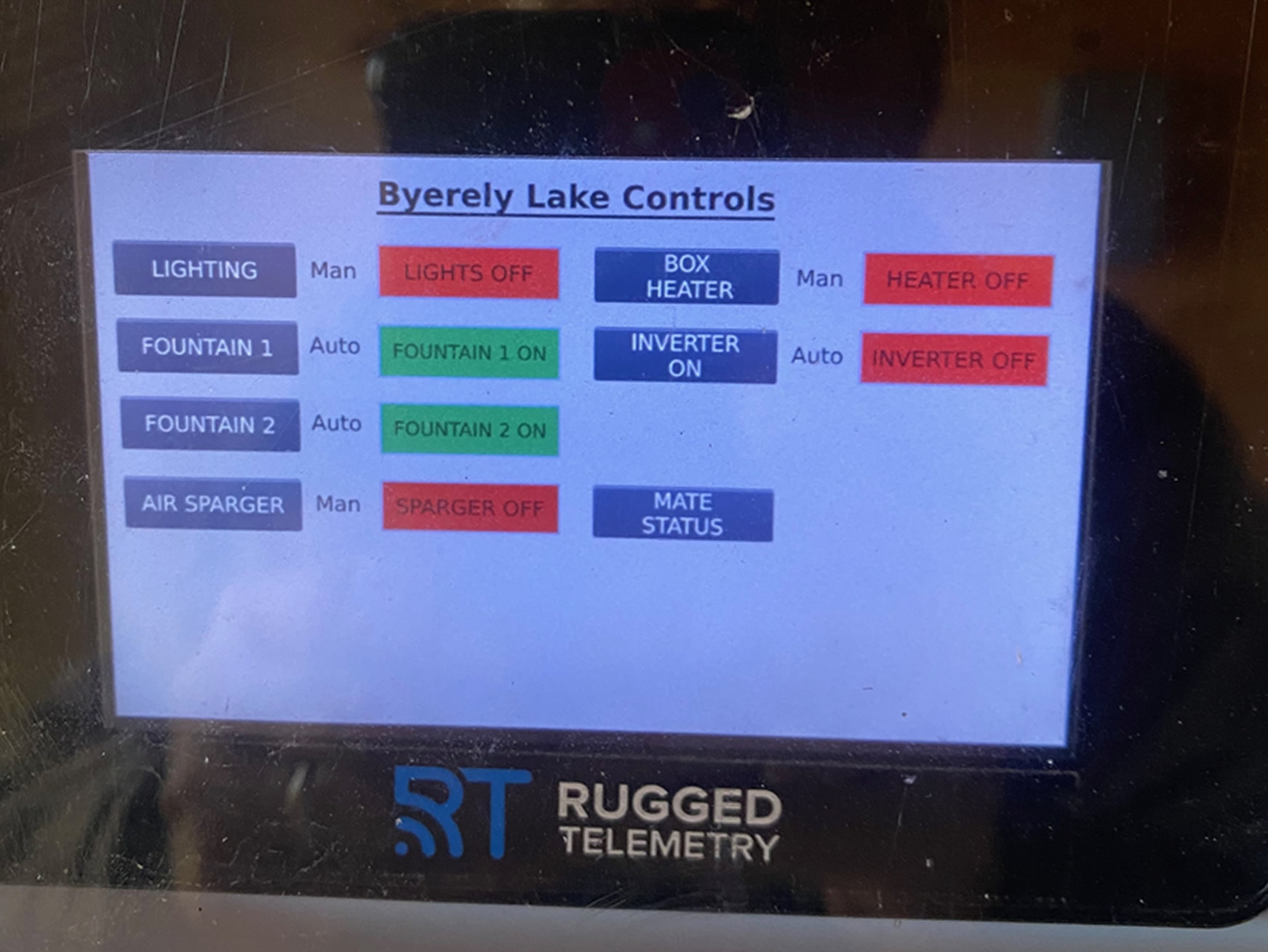

A Solar Power System has been installed at a 1.7 acre lake on the North Danville Bypass. This Solar Power System is used to power two fountains, an air compressor, four bottom aeration pads, a controller system, a 110V electrical outlet, and a camera.

This body of water is an impoundment lake and was built in 1998(?) to contain rainwater runoff from the west side of the Danville bypass. The lake has an adjustable runoff weir that empties into a local creek. The lake has an approximate depth of only ~5 feet. Since the danger of Lake Turnover is mainly present in lakes of greater than 10-15 feet in depth Bottom Aerators are not necessarily needed. However, they were added in this case to test out their operation and their control.

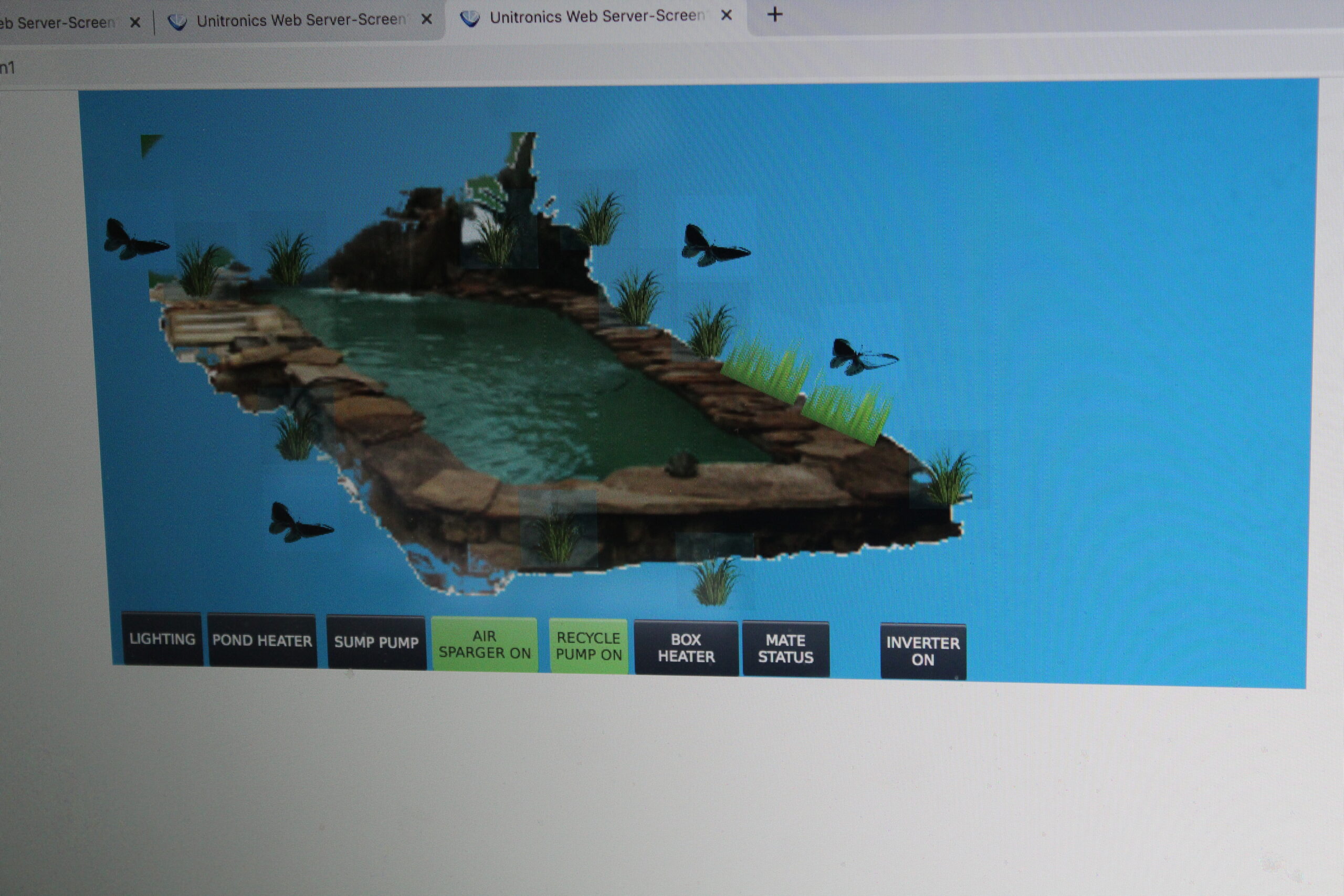

Small Ornamental Pond

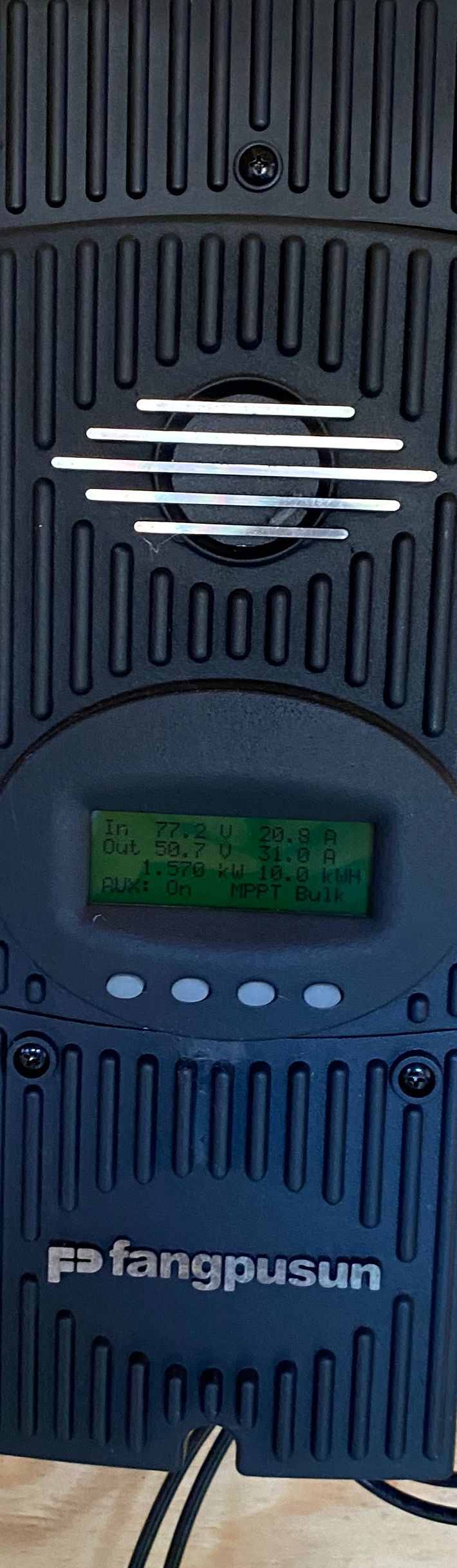

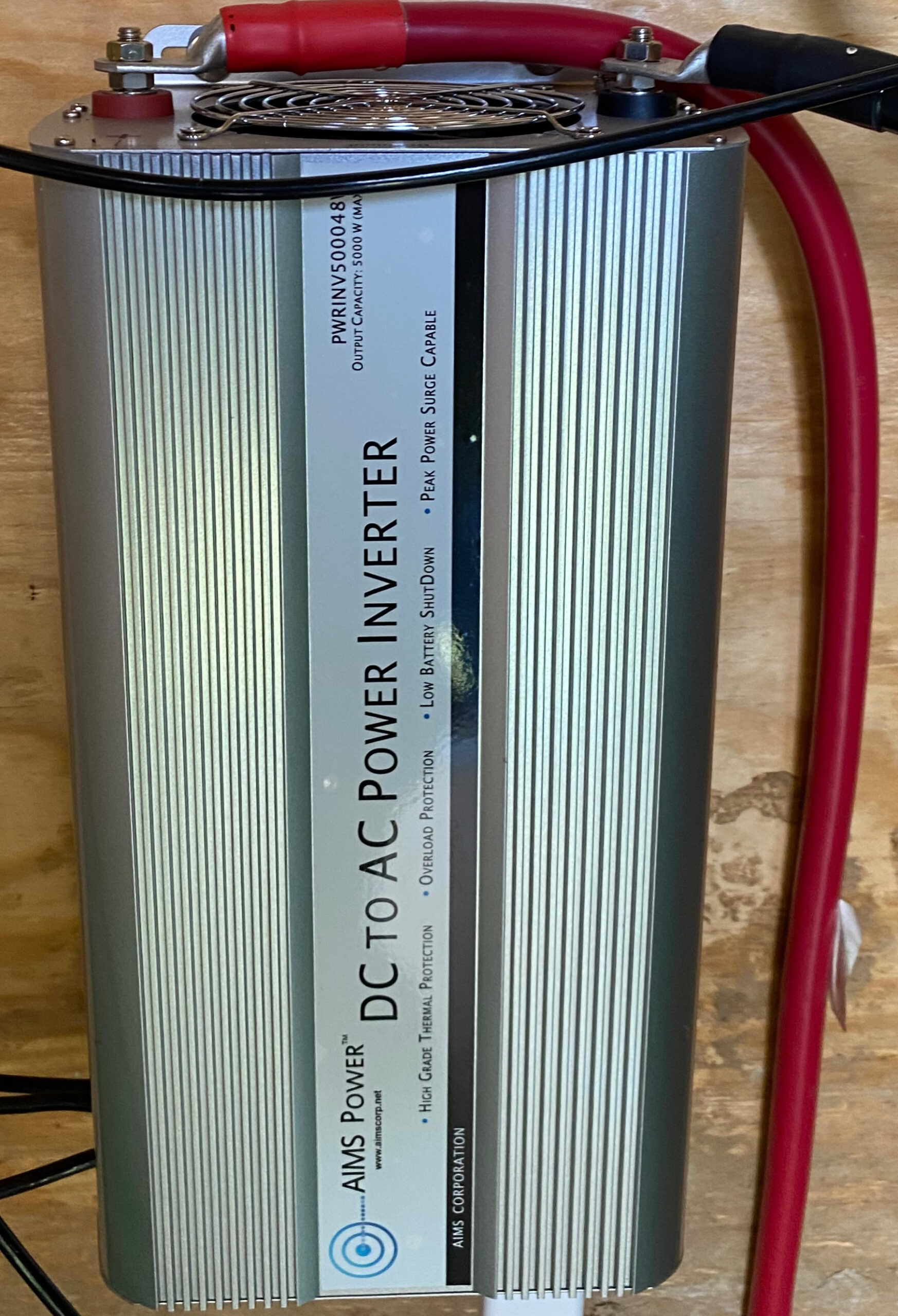

An example is shown below of a small Ornamental Koi Pond. This pond is in the front lawn of a Business in an Industrial park in Danville. It contains two bottom aeration pads and a recycle pump, with a filter. The air compressor and the recycle pump are powered by four ground mounted 300 watt Solar Panels and controlled with a Microcomputer. The Micro Computer signal is sent to the company office computers via an Electrical Bridge. The outside equipment can be controlled and programmed remotely. A process sketch is given below. The DC power from the Solar Panels is used to charge the Solar Batteries. A DC/AC inverter is then used to convert the power from the Batteries to Alternating Current. This alternating current is then used to power the recycle pump/filtration system, the air compressor for the two bottom aerators and the control system.

A microcomputer system is used to remotely control the recycle pump and the bottom aerators.

The electrical process diagram for both of these cases is similar and is given below.

Process Diagram

-

Solar Panels

-

Direct Current (DC) -

-

Charge Controller

-

DC-

-

Solar Batteries

-

DC-

-

DCAC

Electrical Inverter

-

Alternating Current (AC) ∿

-

Process Controller

Remote Monitor / Controller -

AC∿

-

Loads

-

AC∿

Grundfos “Gator”

1.5 Hp 115V

Centrifugal Pump -